Supply Chain Management (Suppliers)

Origin discloses the Origin Group's procurement policies and other information to ensure that the entire supply chain engages in fair business practices.

Origin has established a new "Sustainability Policy" and a "Sustainability Committee" headed by the President and Representative Director and consisting of executive officers in charge of business divisions, with a focus on not only “Corporate Social Responsibility” but also “Sustainable growth and medium- to long-term enhancement of corporate value" We have also declared a mid-term reduction target of 50% reduction of our own CO2 emissions by 2030 (from the 2015 level) in order to contribute to carbon neutrality.

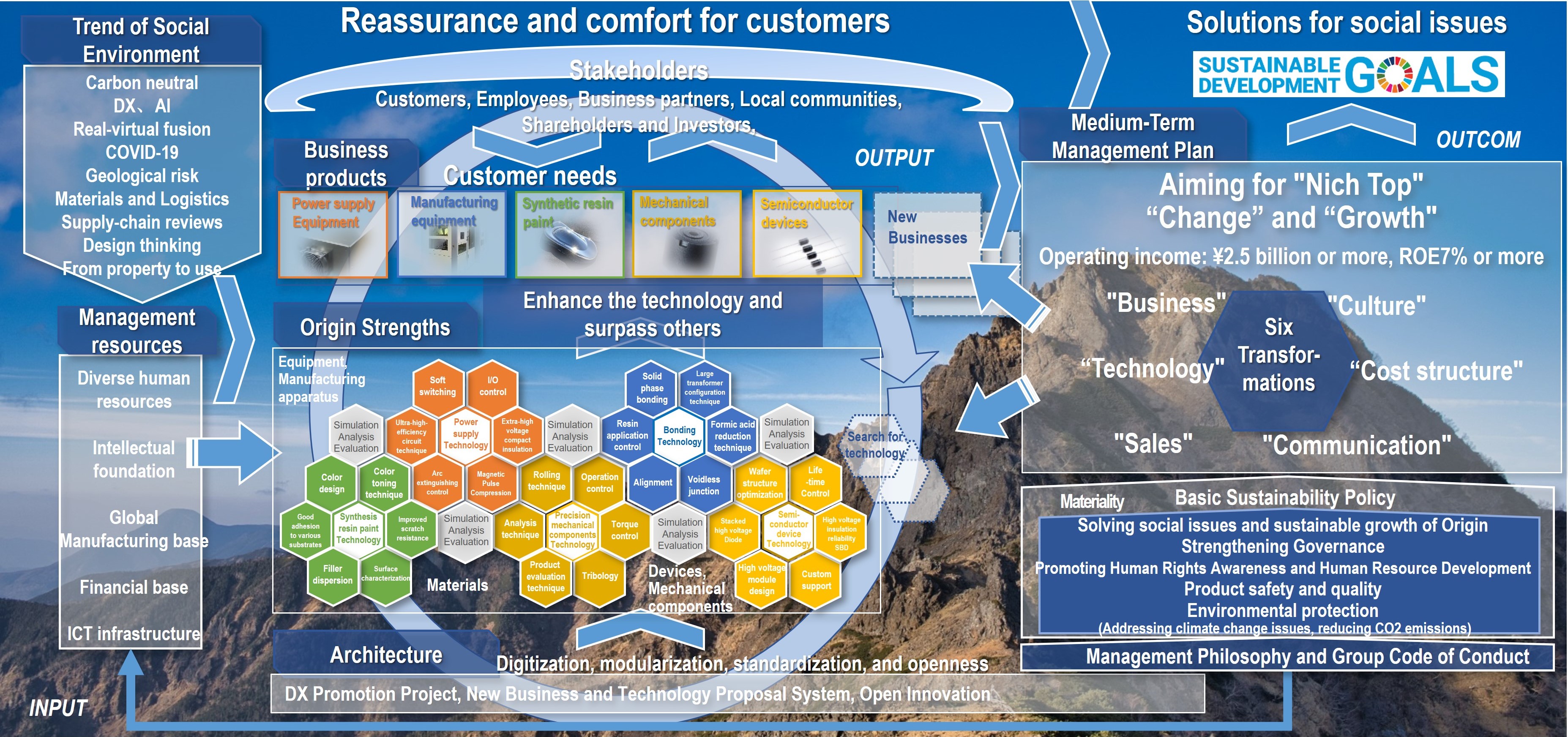

Origin develops its business by utilizing management resources centered on technologies, which are its original strengths, under its management philosophy and sustainability policy, while grasping trends in the social environment. With the aim of becoming a "niche top" in our medium-term management plan, we will pursue the exploration of new technologies and the creation of new businesses under our “Change" and “Growth," thereby providing customers with reassurance and comfort and also contributing to the solutions for social issues.

Message from the

Message from the Sustainability management and CSR concept Explanation of our sustainability management initiatives, including our basic sustainability policy and materiality.

Sustainability management and CSR concept Explanation of our sustainability management initiatives, including our basic sustainability policy and materiality.  Business Activities

Business ActivitiesSupply Chain Management (Suppliers)

Origin discloses the Origin Group's procurement policies and other information to ensure that the entire supply chain engages in fair business practices.

Working Toward Carbon Neutrality

Origin has set a mid-term reduction target for the entire supply chain for 2030 to contribute to carbon neutrality by 2050.

Origin's Digital Transformation (DX)

In September 2020, Origin will launch a DX promotion project consisting of representatives from each organization to fundamentally review each business process to achieve the ideal state and strengthen DX initiatives.

Origin is actively working to contribute to the sustainable development of its business and the realization of a sustainable society in each of the ESG (environment, society, and governance) themes.